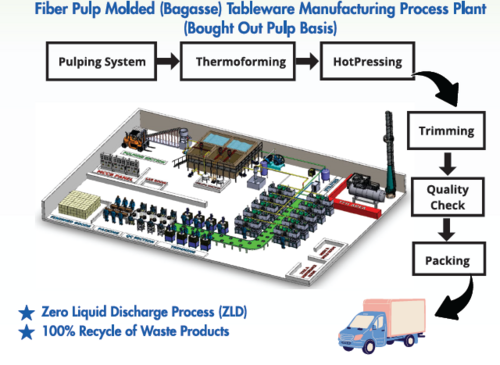

About FIber Pulp Molded (Bagasse) Tableware Manufacturer Process

Ecosure Pulp molding Technologies Limited is an Uttar Pradesh, India-based manufacturer and supplier of premium range of Edge Trimming Machine units that are designed and developed by our team of professional engineers using heavy-duty materials and high-performance drives that gives high durability and robustness. They are available in fully automatic and semi-automated variants as per the order placed by the clients.

Advanced Wet Pressing TechnologyOur machines utilize wet pressing with mold heating-using either electric or customizable steam sources-to shape bagasse pulp into sturdy, biodegradable tableware. This technique ensures precision in forming plates, bowls, trays, and more.

Integrated Online Drying for EfficiencyAn online drying system is built into the production process, improving cycle speed and reducing manual intervention. Each production cycle takes just 15-30 seconds, supporting rapid manufacturing and consistent product quality.

Automated and User-Friendly OperationComplete with PLC control and automatic operation, the system streamlines workflow with quick-change molds and integrated pulp handling. Operators benefit from reduced labor requirements, intuitive controls, and flexible voltage compatibility (380-415V, 50/60Hz).

FAQ's of FIber Pulp Molded (Bagasse) Tableware Manufacturer Process:

Q: How does the Fiber Pulp Molded Tableware Manufacturing Machine operate?

A: The machine uses wet pressing with heated molds (electric or steam) to form bagasse pulp into tableware items. It integrates pulp agitation, filtration, automatic PLC control, and online drying for a streamlined manufacturing process.

Q: What raw materials are suitable for this manufacturing process?

A: This system is designed to handle bagasse pulp, which is derived from sugarcane residue, and can also process waste paper as an optional ingredient. These materials help produce environmentally friendly biodegradable tableware.

Q: When should manufacturers consider using quick-change mold configuration?

A: Quick-change mold configuration should be used whenever there is a need to switch between different tableware shapes or sizes, maximizing production flexibility and reducing downtime during mold transitions.

Q: Where is the ideal location for installing this tableware manufacturing machine?

A: The machine is suited for factory environments or industrial production units in India, especially those focused on eco-friendly products. It requires an area with adequate space, water supply (800-1200 L/hr), and 380-415V electrical connectivity.

Q: What is the production capacity and cycle time of the machine?

A: Depending on the model, the machine can produce between 2000-6000 pieces per hour, with each cycle taking 15-30 seconds. Capacity may vary based on tableware design and settings.

Q: How does the integrated online drying system enhance the manufacturing process?

A: The online drying system allows immediate drying of molded products during the continuous production cycle, reducing manual handling and improving overall efficiency and product uniformity.

Q: What are the primary benefits of using bagasse-based fiber pulp molded tableware machines?

A: Manufacturers benefit from high-speed automatic production, sustainable biodegradable outputs, reduced labor requirements, quiet operation ( 75 dB), and flexibility in design through quick-change molds. This supports eco-friendly initiatives and operational efficiency.